What developments are there in the use of 3d printing in the medical field? It was discussed at CPhI 2016. Here is what emerged.

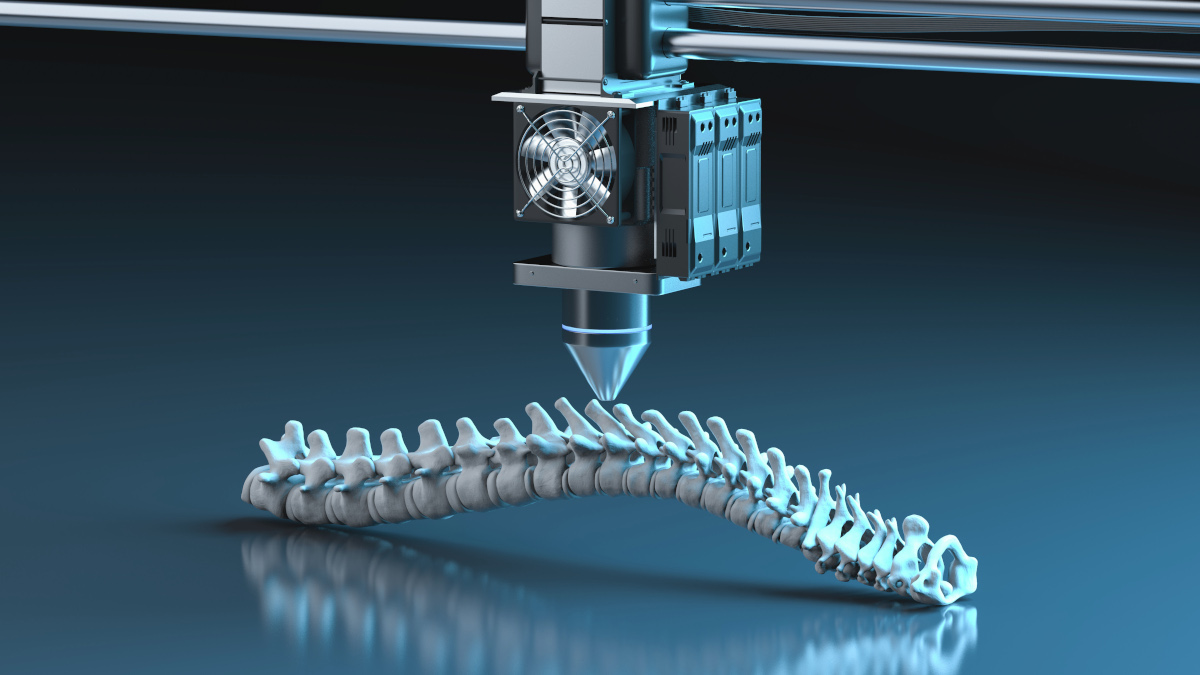

In these last years the 3D printing technology is creating a sensation especially in medical field, extent that this last one could be completely revolutionized. It is already used to create prosthetics, implants and personalized drugs custom-made for each patient, with the prevision to create entire vascularized organs, like hearth, liver and kidney.

The tridimensional objects printing has origins in stereolithography developed in the 80’s by Charles Hull. Obviously today is far more advanced: it starts from a digital model, created with an appropriate software, that is then elaborated and recreated by 3D printers. The printing is performed by layers until the realization of the entire object, using particular inks that can be composed of materials such as plastics, metals, ceramics, powders, liquids or even living cells.

In medical sector there are various objects that are already printed thanks to this technology: anatomical models, implants, prosthesis and drugs, that can be entirely personalized, and even tissues and organs.

In future it will possible to print replacement organs for patients that are waiting for a transplant, starting directly from cells removed from their own body. This will minimize the risk of rejection and will eliminate the wait, often fatal, of the compatible organ.

The 3D printing is already reality in many sectors: in dentistry it is used for the creation of teeth and implants; in orthopedics custom-made prosthesis are created; in neurosurgery it is used to print parts of cranial plate that perfectly fit, despite the human cranial complexity.

Many are the examples of success. In addition to the personalized creation, that eliminates the need to shape the pieces, this innovative method also offers other benefits like the limited costs, the rapidity of objects realization limited to a few hours, and a greater collaboration among researchers, who have the possibility to share 3D printing data files thanks to already active open-source databases.

And in pharmacology?

Also in the specific area of the pharmacology, the 3D use promises to be revolutionary. The scenarios that it opens provide benefits such as the production of drugs with a precise control of the dosage and a high repeatability. Moreover, the pharmacist will be able to generate custom–made drugs, and APIs of more medicine will be able to coexist in a unique pill, in function of the patient needs and his specific profile. The traditional drug forms on the market provide, instead, standard release of active ingredients. The 3D will allow the creation, in a unique medicine, of ingredients layers able to differentiate, in a controlled and personalized way, the APIs release.

There are, however, different crucial points, such as issues regarding timing and project development costs, copyright and patent protection, the high risk of drugs counterfeiting and, overall, the missing of clear rules. The regulatory decisions have to be taken over solid scientific and technological bases. With this aim, FDA has set up a working group in order to verify the technical and regulatory questions about 3D in medical field.

It has been recently pointed out by Emil W. Ciurczak of Doramaxx Consulting, speaker at CPhI 2016, who has also highlighted how many changes have been inspired from those Agencies that previously had been accused of blocking progress, FDA, EMA and ICH have, in fact, recently elaborated and spread guidelines to regulate the process.